What is it EN 12642-XL?

Here at Montracon, we are always looking at new ways to increase driver safety. EN 12642-XL plays a huge role in driver safety and as one of the market-leading trailer manufacturers, we have the approval to build EX12642-XL GRP Box Vans, Postless & Posted Curtainsiders, and Flats. So what is EN12642-XL?

What is EN 12642-XL?

EN 12642-XL is a European load containment standard for the complete body structure of commercial vehicles and trailers. The standard applies to body structures (either trailers or rigid bodies) with a GVW over 3500kg. This standard sets out basic minimum requirements for the side walls (and or curtains), front and rear walls and must be tested by an accredited body such as German TUV or the UK VCA.

The rating can be issued (and must be marked clearly on the vehicle) when the test criteria for all areas have been met. For curtainsiders, the rating is not limited to the curtains themselves and must be applied to both curtains and supporting bodywork.

Test Methodology:

XL testing can be determined using one of two types of test: static and dynamic.

On test

Static Type.

The test encompasses an immovable flat surface, placed 50mm to the inside of the body. An inflatable bag is then placed between the flat surface and the body is inflated so that it exerts the correct test force over the specified test area. The specified test force must be applied for at least 5 minutes and after the test is finished the body structure should not show either permanent deformation or changes which would impair its intended use.

1. Under 100% force, there must not be any temporary deformation exceeding 300mm.

2. Under 100% force, there must be no permanent deformation exceeding 20mm.

3. Under 85% force, there must be no permanent deformation.

The “Force” is defined as a constant force, applied at right angles to the surface it is being applied to.

Dynamic Test

With a Dynamic test the trailer is loaded. The cargo must be evenly distributed the full length and a minimum of ½ the overall height of the trailer. Once loaded the trailer is dr

iven around a test track at a constant speed incorporating numerous manoeuvres within each lap of the track. The trailer must complete a minimum of 3 consecutive laps of the test track.

In conjunction with the cargo, accelerometers are fitted to the trailer. The accelerometers measure the lateral and longitudinal acceleration on both the trailer and the cargo.

For the trailer to pass the dynamic test, if the cargo is contained by the trailer structure (ie simply loaded into the trailer with no lashing equipment used), there must be no permanent deformations or tears in the walls or connections to the frame. If the cargo is secured by lashing equipment then no display of damage should be evident.

Forward Braking

- Sensor requirement 0.8g

- At a speed of 35 to 40km/h

- One vehicle length before braking a ground sleeper is driven over

- 3 consecutive tests

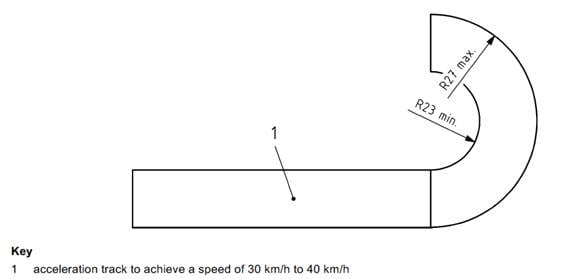

‘J’Curve (Transverse acceleration)

- Sensor requirement 0.5g

- Entry speed 30 to 40km/h

- On entry to the circular track the required speed must be achieved to record the required 0.5g

- 3 consecutive tests

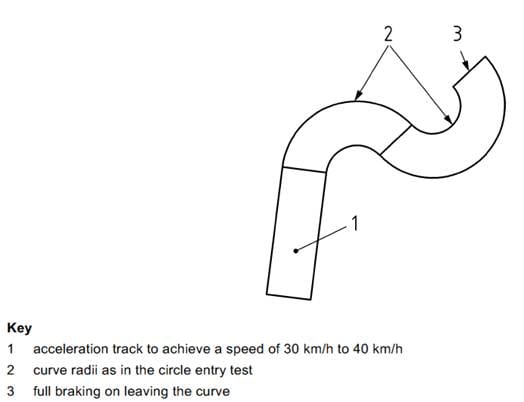

‘S’ Curve (Change of lane test)

- Sensor requirement 0.5g

- At an initial speed of 30km/h

- Path followed as shown with 0.5g required during the

transition between left and right curves. - 3 consecutive tests

Reverse Braking

- Sensor requirement 0.5g

- At a speed of maximum reversing speed.

- 3 consecutive tests

Correct Markings

Examiners should be able to identify an XL rated trailer by the decals attached to the vehicle (example shown below).

The decals must be affixed to the bodywork on all four sides, bulkhead, rear and both sides of the vehicle

It is also important the decal states ‘XL’ and not ‘L’, as ‘L’ simply denotes a curtainsider fitted solely with XL curtains. It is also important that the wording shown on the sticker stipulates ‘This vehicle body complies with the standard EN 12462 XL’.

We are aware of trailers which have very similar stickers with wording along the lines of ‘These curtains have been manufactured to suit bodywork with the standard EN 12461 L’.

In effect, these are standard trailers which have been fitted with the curtains associated with XL trailers. These trailers typically do not have the reinforced roof, bulkhead and rear doors expected on a XL trailer. We are reliably informed that more often than not the roof of a trailer is likely to give way before the curtains (in test conditions), and as such, the additional materials in an XL trailer are key to its success.

Flat/Platform Headboards

In addition to full bodied vehicles, EN12642-XL also applies to the headboard on flat/platform products. An option we can offer.

Testing

The structural strength and the form stability of the headboard is tested using direct stressing of the cargo bay edges by excerting test forces with a pneumatic test rig. The test must take place with the headboard in its intended operating condition and with all body/structural components in their operational position.

The use of a test rig allows all reactive forces to be applied directly into the trailer floor. The application of the testing forces allows the strength and rigidity of the entire body to be tested.

Our XL headboard is rated at 37,000Kg payload at 1500mm high (covered up to 2000mm high).

The standard headboard @ 1500mm high is rated at a 20000 Kg payload. Both TUV tested and certified.

If you would like anymore information about Montracon EN12642-XL products, feel free to contact us on 01302 732500 or email sale@montracon.com

Useful Links:

Load security for XL-rated vehicles: https://movingon.blog.gov.uk/2014/09/22/load-security-for-xl-rated-vehicles/

Load securing: vehicle operator guidance: https://www.gov.uk/government/publications/load-securing-vehicle-operator-guidance/load-securing-vehicle-operator-guidance